WEFLO H-Strainer Fig.7120

Specifications :

- Large Flow Area, Low Pressure Drop.

- Service without removal from line.

- Can be installed in any position, spec installation with cover up is recommended.

- Flanged and Drilling comply with EN1092-2 PN16. Other flange types are available upon request.

- Rated Working Pressure 200 psi/16 bar.

Description

Reviews (0)

Be the first to review “WEFLO H-Strainer Fig.7120” Cancel reply

Shipping & Delivery

Related products

WEFLO Waste Cone FIG.8103

Specifications:

- Available for Onshore and Offshore Applications.

- Manufactured in Accordance with NFPA20 Requirements.

- Designed for use with UL/FM Approved Fire Pump Pressure Relief Valves.

- Flanges to A N S I Class 150/300, Other available on request.

- Ductile lron-ASTMA536-65.

- (2)2"316 SS Sight Glasses per Waste Cone.

- Single Body Casting(No Welding).

WEFLO Y-Type Strainer, Flanged Ends, FIG.F0511-175

Specification :

- Meet or exceed the requirements of UL 321 Standard.

- NPT or BSPT blowoff outlet on cover (blowoff outlets are furnished with plugs).

- Recessed seat in body assure accurate screen alignment

- Round holes with 60 degrees staggered.

- Excellent flow characteristics and low pressure losses at high flow rates.

- Connection Ends: ASME B16.1 Class 125 0r EN1092-2 PN10/16(Other Flange Types Available Upon Request)

- Rated Working Pressure 175 psi.

- UL321/ULC Listed.

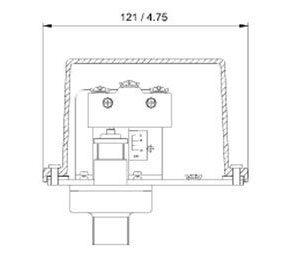

WEFLO Pressure Switch FIG.WPS

Features

Maximum Adjustment Pressure Range:WPS10-1/WPS10-2:4-20 psi.

WPS40-1/WPS40-2:10-100 psi.

WPS120-1/WPS120-2:10-200psi.

Factory Setting:

WPS10-1.WPS10-2: 4-8 psi.

WPS40-1:operates at decreasing pressure at 30 psi.

WPS40-2: operates at increasing pressure at 50 psi and decreasing pressure 30 psi.

WPS120-1:operates at decreasing pressure at 110 psi.

WPS120-2: operates at increasing pressure at 130 psi and decreasing pressure 110 psi

Approximate Differential:

WPS10-1/WPS10-2:3 psi throughout range.WPS40-1/WPS40-2:3 psi@ 10 psi& 6psi @ 100 psi.

WPS120-1/WPS120-2:3 psi@ 10 psi& 9 psi @ 200 psi.

Contact Rating:10A@1251250VAC,2.5A@ 30VDCIP 66.

UL/ULC Listed, FM Approved, CE, EAC, VdS, LPCB, 3C certified.

WEFLO Platform Fire Hydrant U246C

Specifications :

Meet or Exceed the Requirements of UL 246C Standard.

NFPA 1963 Standard Nozzle Threads.

Bronze Body and Hose Nozzle.

0-ring Sealed Stem Nut and Hose Nozzle.

Excellent Flow Characteristics.

Multiple Nozzle Configurations.

Monitor Style available.

UL246C Listed, FM Approved.

250 psi Maximum Working Pressure.

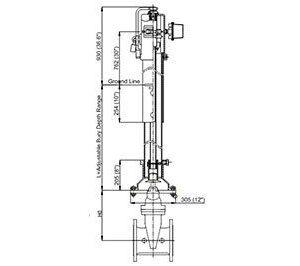

WEFLO Adjustable Vertical Indicator Post FIG.F0800-IP

Specifications :

- Meet or Exceed the Requirements of NFPA 24 Standard.

- Indicates the State of the Valve OPEN or SHUT Position.

- Target Nut to allow 13 to 45 Turns.

- "L" Shaped Wrench Handle fitted with a Secure Padlock(provided by user).

- Protected Windows.

- Telescoping Operating Rod.

- Easily Adjustable indicator OPEN and SHUT Targets.

- UL/ULC 789 Listed and FM1110 Approved.

- CNBOP Certified.

WEFLO Dry-Barrel Fire Hydrant FIG.F0733-250

Specifications:

Meet or Exceed the Requirements of AWWA C502 Standard.

NFPA1963 Standard Nozzle Threads.

Traffic Feature with Duplex Stainless Steel Safety Stem Coupling, Excellent Flow Characteristics.

Multiple Nozzle Configurations.

Mechanical Joint Base Elbow.

Dry Top Design with O-ring Sealed Oil Reservoir.

Dual Auto-frost Bronze Drain Valves as Standard

UL246 Listed and FM 1510 Approved. Rated Working Pressure 250 psi. Certified to NSF/ANSI61&372

WEFLO Backflow Preventers – Double Check Valve FIG.F5410

PRODUCT FEATURES :

- A double check valve is a testable device designed for use in 'medium hazard conditions to prevent backflow caused by back-siphonage or back-pressure. It is intended for use under continuous pressure conditions. The DCV have two check modules.

- Multiple Ends Types: Flange by Flange, Flange by Groove, Groove by Groove.

- Pressure Rating:175psi/12bar

- Working Temperature: Cold Water, not exceeding 60°C.

- Horizontal only. UL/ ULC Listed.

WEFLO Y-Type Strainer, Grooved Ends, FIG.F0522-175

Specification :

- Meet or exceed the requirements of UL 321 Standard.

- NPT or BSPT blowoff outlet on cover (blowoff outlets are furnished with plugs).

- Recessed seat in body assures accurate screen alignment Round holes with 60 degrees staggered.

- Excellent flow characteristics and low pressure losses at high flow rates.

- Grooved Connections are cut in accordance with AWWA C 606 or other standard Groove Specifications for Steel Pipe.

- Rated Working Pressure 175 psi.

- UL 321 / ULC Listed.

Reviews

There are no reviews yet.