WEFLO Backflow Prevention Devices SCV – SCDA – DCV

Description :

A single check valve is designed for use in “low hazard” conditions in services to prevent backflow caused by back-siphonage or back-pressure.

It is intended for use under continuous pressure conditions.

The check is designed to maintain a minimum of 1 psi across the check valve during normal operation.

Multiple Ends Types: Flange by Flange, Flange by Groove, Groove by Groove.

Description

Reviews (0)

Be the first to review “WEFLO Backflow Prevention Devices SCV – SCDA – DCV” Cancel reply

Shipping & Delivery

Related products

WEFLO Russia-Fire Hydrant FIG.8220

WEFLO Backflow Preventers – Double Check Valve FIG.F5410

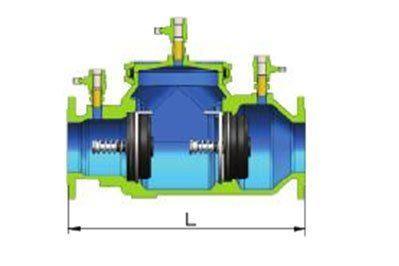

PRODUCT FEATURES :

- A double check valve is a testable device designed for use in 'medium hazard conditions to prevent backflow caused by back-siphonage or back-pressure. It is intended for use under continuous pressure conditions. The DCV have two check modules.

- Multiple Ends Types: Flange by Flange, Flange by Groove, Groove by Groove.

- Pressure Rating:175psi/12bar

- Working Temperature: Cold Water, not exceeding 60°C.

- Horizontal only. UL/ ULC Listed.

WEFLO Vane-Type Waterflow Detector GIF.F6001S

Features :

- Equipped with tamper resistant screws to prevent unauthorized entry.

- The F6001S fits 1", 1%",1%", and 2" brass and copper threaded tees, in addition to 1 "and 1½" CPVC tees.

- Clearly marked plastic paddles are included to fit the different installation configurations.

- One switch is enclosed in the detector.

- Terminals are easy to read and wire.

- Designed and built for accuracy and repeatability.

- Rated Working Pressure: 300 psi.

- Flow Sensitivity Range for Signal: 15-37.8 L/min (4-10GPM)

- Contact Ratings: 8Aat125/250VAC, 3Aat 24VDC.

- Maximum Surge: 18 FPS (5.5m/s)

- UL/ULC Listed

- EAC and CE Certified.

WEFLO Y-Strainer FIG.7101 – 7102

Specifications :

- NPT or BSPT blowoff outlet on cover. Blowoff outlets are finished with plugs.

- Screens are perforated 304 stainless steel with spot welded seam.

- Recessed seat in body assures accurate screen alignment.

- Flanged and drilling complies with EN 1092-2 PN16 / 25, ANSI B 16. 1 Class 125.

- Rated Working Pressure Fig. 7101:16 bar / 200 psi for DN 50 to DN 600 ,Fig. 7102:25 bar / 300 psi for DN50 to DN 300

- WRAS Approved: Fig.7101 DN50-DN 600 Dl body, EPDM Gasket for potable water.

- ANSI/ NSF61 & 372 Certificated: Fig: 7101: DN 50-DN 2000.

- For larger than DN600 product data, contact the supplier.

WEFLO Explosion-Proof Vane-Type Waterflow Detector FIG.F6001EX

Specifications :

- Designed and approved to operate in hazardous locations.

- Two synchronized switches are enclosed outside of explosion environment.

- Terminals are easy to read and wire.

- Built-In mechanical time delay feature; minimizing the risk of false alarms due to pressure surges or air trapped in the system.

- Offers excellent performance during riser vibrations caused by large in-rushes of water.

- Designed and built for accuracy and repeatability.

- Hazardous Atmosphere Classification: Class I: Div. 1. Groups C, D T6; Class I: Div.2,Groups C,D T6; Class II: Div.1,Groups E,FG T6; Class II: Div.2,Groups F GT6: Class III. DNV 22 ATEX 17663X; IECEx DNV 22.0041X; Ex db lB T6 Gb; Ex tb llC T8O'c Db Ip66

- Maximum pressure:

- Flow sensitivity range

- Contact rating

- Maximum Surge: 18FPS (5.5m/s)

- Entry Size: 1/2"NPT threaded conduit connections

- NEMA 4/ P66 Rated enclosure rating

- Ambient Temperature: 0'C to 49C

WEFLO Wet-Barrel Fire Hydrant FIG.F1311 F1311B-250

Specifications :

- Meet or Exceed the Requirements of AWWA C503 Standard.

- NFPA1963 Standard Nozzle Threads.

- Excellent Flow Characteristics.

- Multiple Nozzle Configurations.

- Inlet Flange to ASTM B16.1 Class 125, size 6in.

- Rated Working Pressure 250 psi.

- UL246 Listed and FM 1511 Approved.

- NSF/ANSI61&372 certified forF1311B-250 Fire Hydrant.

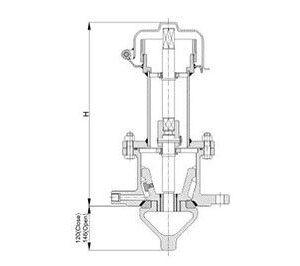

WEFLO Waste Cone FIG.8103

Specifications:

- Available for Onshore and Offshore Applications.

- Manufactured in Accordance with NFPA20 Requirements.

- Designed for use with UL/FM Approved Fire Pump Pressure Relief Valves.

- Flanges to A N S I Class 150/300, Other available on request.

- Ductile lron-ASTMA536-65.

- (2)2"316 SS Sight Glasses per Waste Cone.

- Single Body Casting(No Welding).

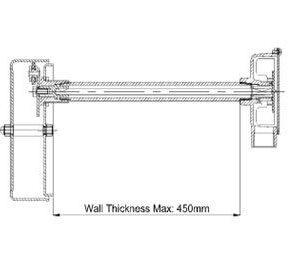

WEFLO Water Motor and Gong, FIG.WMA-16

Operation :

When a Deluge Valve is activated, water flows through the valve's trim, discharges to a strainer and into the water motor inlet, From the inlet, the water flows through a nozzle which directs the stream to the impeller. The stream turns the Impeller and drive shaft, causing the striker arm to rotate, thus producing a continuous alarm. The water is discharged thro-ugh a 1"(25mm) drain outlet at the bottom of the impeller ho-using. The discharged water must be piped through the wall to a suitable open drain.

Reviews

There are no reviews yet.