Valve Accessories

Showing 13–24 of 82 results

WEFLO Vane-Type Waterflow Detector, CPVC & Bronze Adapter- FIG.F6001U

Features:

Equipped with tamper resistant screws to prevent unauthorized entry. The F6001U with CPVC adapter fits 1",1%",1%", and 2" CPVC tees The F6001U with bronze adapter fits 1", 1¼", 1%", and 2" brass and copper threaded tees, in addition to 1" and 1%" CPVC tees. Clearly marked plastic paddles are included to fit the different Installation configurations. Two synchronized switches are enclosed in a durable terminal block. Terminals are easy to read and wire. Built-In mechanical time delay feature; minimizing the risk of false alarms due to pressure surges or air trapped in the system. Offers excellent performance during riser vibrations caused by Large in-rushes of water.

Designed and built for accuracy and repeatability.

Rated Working Pressure: 175 psi.

Flow Sensitivity Range for Signal:15-37.8 L/min(4-10GPM)Contact Ratings:8Aat125/250VAC,3Aat 24VDC,2.5Aat 30VDCMaximum Surge:18FPS(5.5m/s)

UL/ULC Listed, FM Approved.

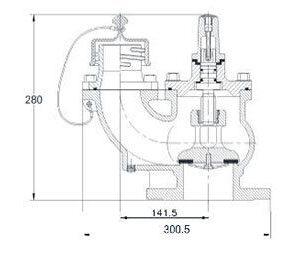

WEFLO Russia-Fire Hydrant FIG.8220

WEFLO Grooved Ends Y- Strainer FIG.7901

Specifications :

- NPT or BSPT blowoff outlet on cover. Blowoff outlets are finished with plugs.

- Screens are perforated 304 stainless steel with spot welded seam.

- Recessed seat in body assures accurate screen alignment.

- Groove dimensions comply with Metric or AWWA C606 standard.

- Rated Working Pressure 16 bar/250 psi.

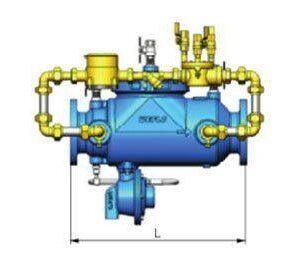

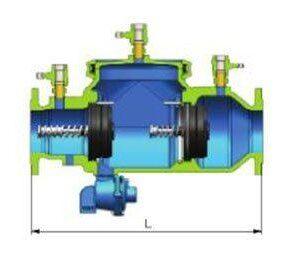

WEFLO Backflow Prevention Devices DCDA – RPZD – RPAD

WEFLO Underground Fire Hydrant FIG.F9207

Specifications :

- Meet or Exceed the Requirements of BS EN 14339 Standard.

- Ductile iron Construction.

- 2 1/2 " London Round Thread Outlet to BS 750.

- Corrosion Resistant Construction, Compliant with BS EN 1074-6 for Disinfection Products.

- Universal Drilled Inlet Flange BS EN 1092-2, BS 10 Table D/E

- Auto-frost Drain Valve as Standard.

- Excellent Flow Characteristics.

- Multiple Outlets Configurations.

- Rated Working Pressure 16 bar.

- WRAS Approved.

WEFLO Vane-Type Waterflow Detector GIF.F6001S

Features :

- Equipped with tamper resistant screws to prevent unauthorized entry.

- The F6001S fits 1", 1%",1%", and 2" brass and copper threaded tees, in addition to 1 "and 1½" CPVC tees.

- Clearly marked plastic paddles are included to fit the different installation configurations.

- One switch is enclosed in the detector.

- Terminals are easy to read and wire.

- Designed and built for accuracy and repeatability.

- Rated Working Pressure: 300 psi.

- Flow Sensitivity Range for Signal: 15-37.8 L/min (4-10GPM)

- Contact Ratings: 8Aat125/250VAC, 3Aat 24VDC.

- Maximum Surge: 18 FPS (5.5m/s)

- UL/ULC Listed

- EAC and CE Certified.

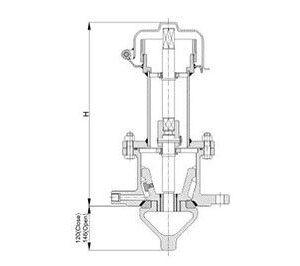

WEFLO Suction Diffuser FIG.7109

Specifications:

- Pump protection fitting, Providing in one single compact unit a reducing elbow.

- a protective strainer and a flow straightener to improve pump performances.

- Removable 20 mesh start up screen for added protection during system start up.

- Oversized diffuser screen.

- Creates a uniform flow to the pump.

- Angled body pattern also designed for reducing pipe size to the pump.

- Drain plug for easy routine cleaning.

- Fully epoxy coated with stainless steel screen for long-lasting corrosion protection.

- Rated Working Pressure 16 bar/250 psi.