Pipe Accessories

Showing 1–12 of 775 results

NIBCO Female Adapter H x FIPT – ABS DWV-FIG No-5803

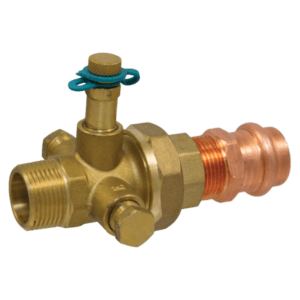

NIBCO BenchPressG® Union P x P – Carbon Steel-FIG No-PCH233

- Operating pressure up to 200 psi cwp depending on the application

- Temperature range -20°F to 250°F depending on the application

- Third party certified to CSA (CSA ANSI LC4/CSA 6.32)

- Third party certified to IAPMO (CSA ANSI LC 4/CSA 6.32)

- NFPA 54 National Fuel Gas Code

- NFPA 58 Liquified Petroleum Gas Code

- NFPA 30 Flammable and Combustible Liquids Code

- NFPA 30A Code for Motor Fuel and Dispensing Facilities and Repair Facilities

- NFPA 31 Standard for the Installatin of Oil-burning Equipment

- ASME B31 Code for Pressure Pipe

NIBCO EPDM Socket Union S x S – PVC Schedule 80-FIG No-4533E

NIBCO 90° Street Elbow Spg x H – PVC DWV-FIG No-4807-2

NIBCO FKM, EPDM Threaded Union FPT x FPT – Black Polypropylene Schedule 80-FIG No-6133-3-3, 6133E-3-3

NIBCO Garden Hose Adapter – Lead-Free-FIG No-NP27GH-LF

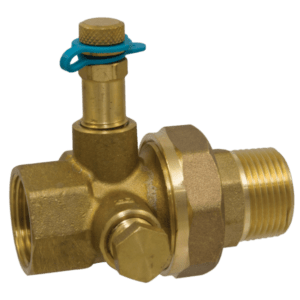

NIBCO Union w/Test Port – FPT Body x MPT Tailpiece-FIG No-TMT-1800

NIBCO Tube Nut – Cast-FIG No-500

NIBCO BenchPress® 45° Elbow Ftg x P – Carbon Steel-FIG No-PC206-2

- Operating pressure up to 200 psi cwp depending on the application

- Temperature range -20°F to 250°F depending on the application

- Third party certified to IAPMO PS-117

- NFPA 13, 13D and 13R

- IRC International Residential Code (ICC PMG)

- IMC International Mechanical Code (ICC PMG)

- UPC Uniform Plumbing Code

- UMC Uniform Mechanical Code

- ASME B31 Code for Pressure Pipe